Concrete Slump Test Definition, Types, Procedure.

The slump of a concrete (or mortar) is determined via a fairly simple test using incredibly simple equipment, comprising a 300mm high hollow steel cone with handles, a steel tamping rod, a steel base plate and a tape measure. This testing apparatus is readily available from contractor's tool suppliers, although all ready-mix suppliers will test.

Slump Test of Concrete, slump cone for Workability Procedure, Apparatus Cement Concrete

Testing for concrete slump is a quick procedure that can be performed on the jobsite using relatively inexpensive, but specialized, equipment. For ready-mix concrete, the procedures for measuring slump are defined by ASTM C143 - Standard Test Method for Slump of Hydraulic-Cement Concrete.

Concrete Slump Test Procedure, Advantages and Limitations

Fresh concrete test data such as slump and air content can help indicate possible causes and guide the troubleshooting investigation. Was excess water added? Was the air content too high or too low? Need your concrete tested? Find concrete contractors near me.

Concrete Slump Testing Background and Procedure

The slump test measures the consistency or workability of concrete. It is used to check the workability of freshly made concrete for the easy placement of concrete. In addition, this test indicates the water-cement ratio and the properties of materials and also admixture, etc. The test is carried out under BS EN 12350-2.

Concrete Slump Test Definition, Procedure And Types Of Slump Test Engineering Discoveries

The slump test's equipment and standard operating procedure are governed by ASTM C 143-20 (Standard Test Method for Slump of Hydraulic-Cement Concrete). The slump cone is the primary piece of equipment used to fabricate freshly mixed concrete samples for the slump test.

Slump Test of Concrete Measure of Workability of Concrete Structural Guide

Concrete slump test or slump cone test is to determine the workability or consistency of concrete mix prepared at the laboratory or the construction site during the progress of the work. Concrete slump test is carried out from batch to batch to check the uniform quality of concrete during construction.

What is the concrete slump test? Intelligent Concrete

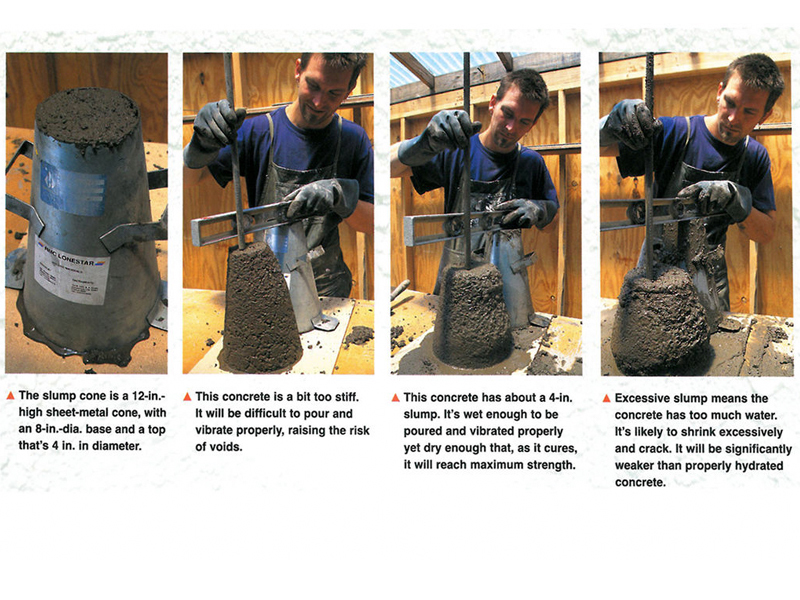

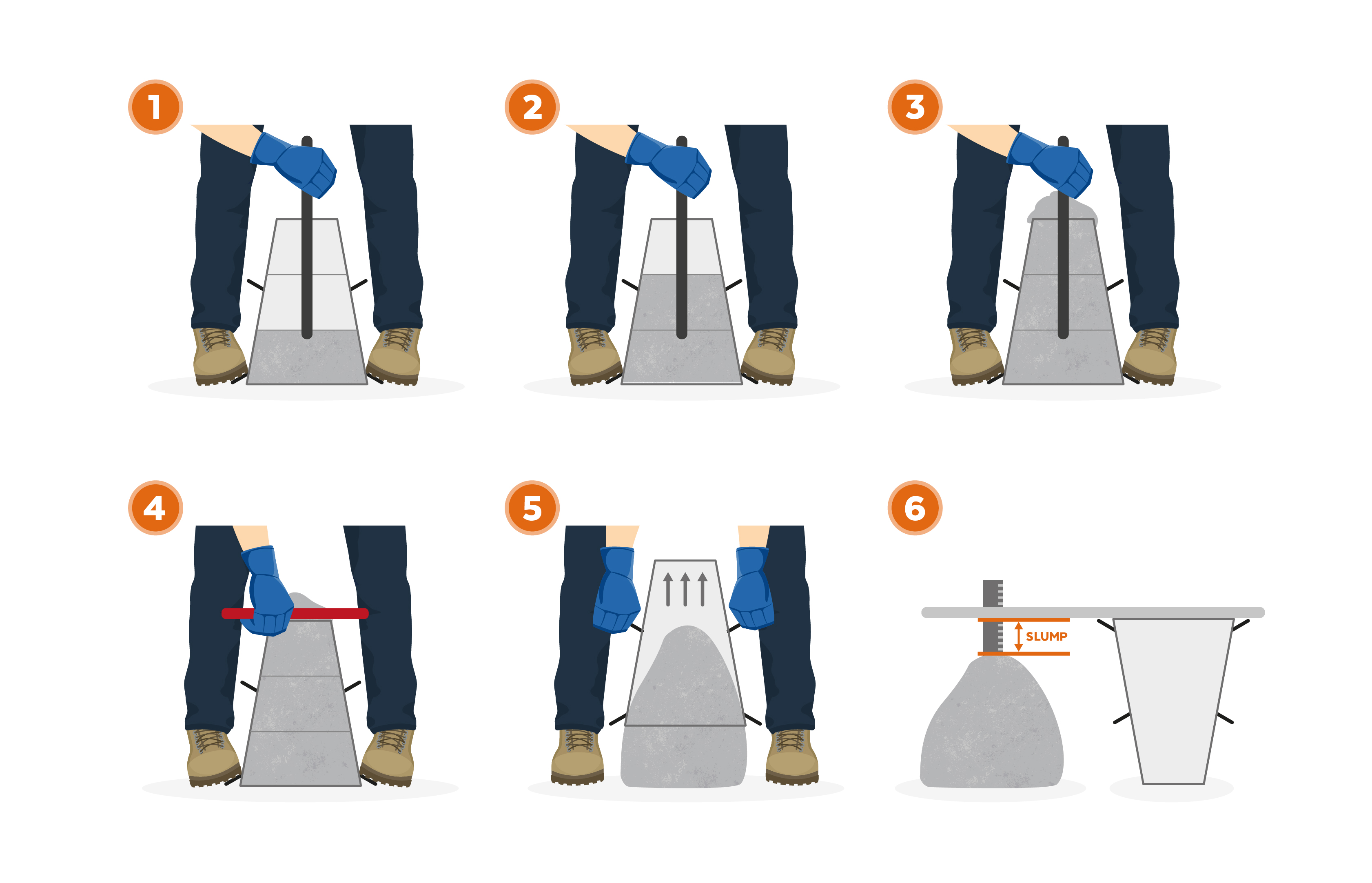

In this test a metal cone 12 in tall is filled with fresh concrete in a specified manner. When the cone is lifted, the mass of concrete "slumps" downward (Figure 4) and the vertical drop is referred to as the slump. Most concrete mixes have slumps in the 2- to 5-in range. 3.3 Portland Cement

Civil Engineering Slump Test of Concrete

Standard Specifications including, but not limited to, slump/slump flow, air content, temperature, unit weight, yield, and other specific contract information. Additionally, the. depending on the class of concrete): Test ASTM AASHTO Slump C143 T 119 Temperature C1064 T 309 Air Content - Pressure C231 T 152 Compressive Strength C39 T 22

Slump Test of Concrete Measure of Workability of Concrete Structural Guide

The slump test is a means of assessing the consistency of fresh concrete. It is used, indirectly, as a means of checking that the correct amount of water has been added to the mix. The test is carried out in accordance with BS EN 12350-2, Testing fresh concrete. Slump test .

Testing Slump in Your Concrete Mix and Why It Is Important Concrete Decor

A slump cone test is performed using a metal mould shaped like the frustum of a cone. With top and bottom diameters that differ, the cone is filled with concrete immediately in three layers. Each layer is tamped using a steel rod to ensure compaction. The tamping rod is used in a uniform manner across the surface of the mould.

Concrete Slump Test Braun Intertec

Definition Concrete Slump Test is a measurement of concrete's workability, or fluidity. It's an indirect measurement of concrete consistency or stiffness. A slump test is a method used to determine the consistency of concrete. The consistency, or stiffness, indicates how much water has been used in the mix.

Concrete Slump Test Concrete Exchange

A concrete slump test is used to determine the correct water content in a batch of concrete. "Slump" is the distance, measured in inches, the concrete settles after the slump cone is removed. A concrete batch with high slump is an indication that the concrete has to much water in it and will likely be weak when fully cured. The ideal mix.

Slump Test for Fresh Concrete Basic Civil Engineering

The concrete slump test measures the consistency of fresh concrete before it sets. It is performed to check the workability of freshly made concrete, and therefore the ease with which concrete flows. It can also be used as an indicator of an improperly mixed batch. The test is popular due to the simplicity of apparatus used and simple procedure.

Concrete Slump Test Definition, Procedure And Types Of Slump Test Daily Engineering

Slump Cone Test of concrete - Civil Engineering lab experiment CHIRANJEEVI RAHUL ROLLAKANTI 196K views 8 years ago

Slump Test Of Concrete Procedure , Advantages & Limitations

Concrete Slump Test The workability or consistency of the concrete mix prepared at the building site or in a laboratory is determined using a slump test, also known as the concrete slump test or a slump cone test . To ensure that the concrete is of consistent quality throughout the construction process, a slump test is performed on each batch.

Concrete Slump Tests Measuring the Workability of Concrete Total Concrete

Concrete slump is a definition of the consistency, often called workability, of concrete. Slump Test. The slump test is defined by ASTM C143 and AASHTO T119 in the United States, and EN 12350-2 in Europe. There is no significant other testing method for concrete workability in industry use today.